ALTHERA

“ALm Technology and Processes for High performing components for aERospace and Automotive"

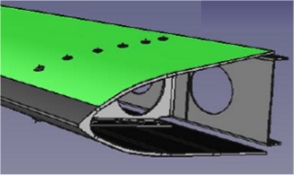

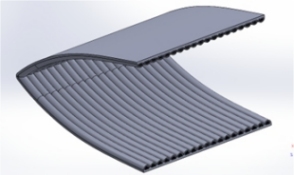

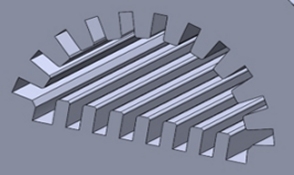

The ALTHERA project aims to develop and perfect a technology, and the processes associated with it, that will allow the additive manufacturing production of structures that are not only light, robust and with high thermal conductivity, but also characterised by particular geometries, both external (in shape) and internal (hollow structures running through channels with very small cross-sections and with singular geometries).

The development of such a technology is essential to promote the advanced digital design and production in ALM of particular heat exchange systems (such as passive and/or semi-passive heat exchangers), characterized by unconventional installation and integration requirements and such as to make them complex if not impossible to implement with conventional technologies. Such solutions are of particular interest for various types of applications and specifically (but not limited to) in the aeronautical and automotive fields.

The technology that is intended to be perfected and customized for these purposes is based on the synergic combination of an advanced metal powder mixing methodology and Additive Manufacturing processes. The complexity of the challenge lies in the use of special Inconel-Cu alloys, developed with an unconventional powder mixing technique, to be used to produce complex objects, with the Selective Laser Melting (SLM) technique.